You can usually only go so low (higher resistor value) on the 'tail' function - they are designed to operate in a given regime - to get dimmer w/o them actually going out altogether a PWM is best. You use the same resistor value for both the brake & tail in that case because it is actually same current through the LED in both cases - just in the 'tail' case, it will be turning on & off, but during the 'on' phase the current will be identical. (You can even use PWM for brake too if you like, just a higher on to off ratio). It's pretty easy to change the timing resistor value (or use a pot) in the PWM so you can play with the intensity till you get what you like.

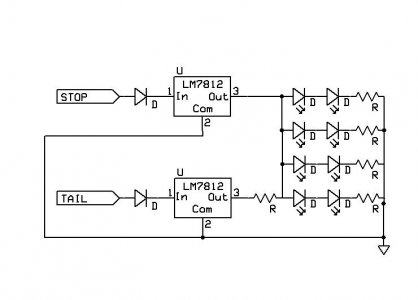

Yes in theory, selecting the 'correct' value of resistor will limit the current at any given voltage - the problem is it will NOT regulate the voltage; you obviously have different conditions for example with just battery & alternator. OK, you can select the resistor using the higher voltage (alternator) as default but this will still do nothing to limit spikes & transients which can actually be quite significant (& what will ultimatley blow your LEDs).

You might also find that you will see quite a different intensity (particularly on the tail function) whether at 12.5V (battery) or vs 15V when car is running.

For a buck & a half

this is cheap insurance! (& just too easy to incorporate not to do it) - There's also a 5 V version from RS if the sum of your 2 forward V's is less than that - or get a 7.5V or 9V from alternative on-line source. Especially if you're sealing it up I'd want to be extra cautious you don't lose any LEDs down the road - will spoil a beautiful effect with 'holes' in your array.