So I have been pretty productive over the past three (3) days. I received a very heavy package from FedEx on Saturday afternoon. It was the EPS, chassis support and other bits. I had everything ready to put it but was concerned that there wasn't enough adjustment in the Outer Toe Links to get a proper alignment. I fiddled and adjusted and measured and remeasured. I just didn't see how this was going to work so I set up the wiring and connectors and just parked it.

About 2AM on Sunday I woke up thinking of how to fix this. I tossed and turned and finally got up at 4AM to start on this project again. I will not be defeated! So I loaded the rack and crossmember on my jack, hoisted it up so I could connect the end links and wrestled the crossmember into place. It bolted into place with very little effort but now I had another dilemma. The end link bearings were still on the OEM rack! After contacting David (NSXMugen) he informed me that the inner tie rods had been created to accept the OEM outer toe links. I was saved! I installed the OEM outers back on the rack and mounted them up. Perfect.

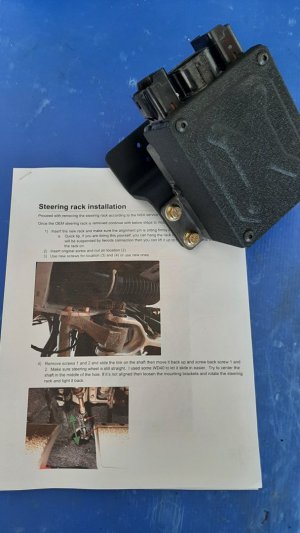

I still needed to amend the battery tray with some additional support bolt holes to attach the tray to the EPS crossmember. Bolts were suppled and the EPS unit is fully mounted and strong. It's not going anywhere.

So today was putting the battery back in the car, finish wiring the four (4) sensor wires for RPM, MPH, Ignition and idiot light and seeing all of my progress. Little did I realize that today, my wife's birthday, I was doomed to fail. First of all the car started right up and I watched the coolant temperature level rise knowing I was going to have to bleed coolant. Again. What I wasn't prepared for was the newly installed Spal fans not operating! Nothing. I shut it down once it reach 200F. WTF? I started digging at connectors and tracing wire and just going nuts. Quick call to

@Coz and we talked thru some scenarios. And then he hit me with the proper order of tracing electronic issues "Did you check the fuse?" Why no, why would I need to do that, it worked fine before. So after replacing the blown 30AMP fuse, the fans fired right up. So did I now start to feel lucky? Read on.

When I did fire up the car I did notice, several times that I did not get the EPS warning light to illuminate when turning the key. It was supposed to flash twice then go out to let me know it was working. It wasn't. So I double checked all the connectors to make sure they were locked. They were. I double checked all of the sensor connections and they were solid too. I removed the gauges again to make sure I had live bulbs in the EPS location and just to make sure, and double checked to see if there was a bulb in the TCS location. Installed the gauge and connectors and fired the car up and no light and no EPS. I changed the idiot light location to the TCS light, still nothing.

So I'll wait to talk with David so I can progress to finish this project. I'm so close.....

Update: So I put the multimeter on several harnesses and the control box too. Power going into the box is confirmed and the ignition lead is hot as well. But no power coming out of the box to the rack itself. Looks like I have a dead control box. David is shpping me another box and should have it Thursday.