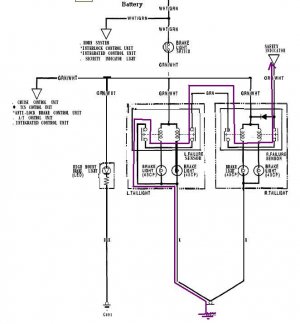

I like the clearcorners execution a lot, but have not purchased because of A) cost B) the brake fault light I am expecting C)the splicing of wires and D) I'd rather the turn LEDs be amber. Picky I know, but it seems like it should be possible to design around without too much hassle.

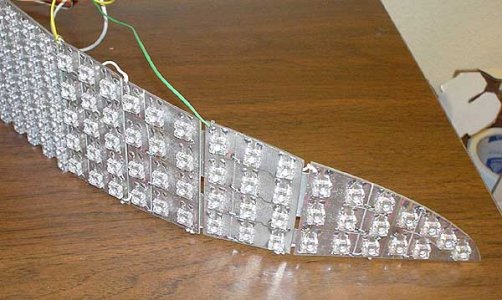

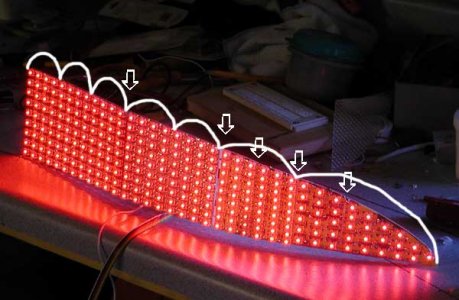

some broken tail light bulbs with wires soldered onto the voltage leads, and filled with rubber/epoxy should be a decent way to connect to the OEM harness. With a breadboard it should be easy (but tedious) to solder all these little LEDs in a criss-cross pattern so that no lights looks like this

- - - - - - - -

- - - - - - - -

- - - - - - - -

Headlights looks like this

- X - X - X - X

X - X - X - X -

- X - X - X - X

Full Brakes Looks like this

X X X X X X X X

X X X X X X X X

X X X X X X X X

When paired up with resistors of the proper values, it SEEMS like the brake fault could be eliminated. Some sandpaper, plastic polish and a candy coating of paint and I could have my ideal tail lights. JDM dark plastic lenses, with an 02+ acura logo in the middle, with Red and Orange LEDs, and all the DOT text polished out.

As you can tell, I have been thinking about this for quite a while. I was hoping that my laziness & frugaillity would combine to push this out of my mind but it has not happened yet. Maybe I should start looking for a spare set of lenses to play with.