Because my idle problem seemed to be SC related I started this new thread.

This is the thread I started with:

idling problem

This morning, with the help of Cees-Jan, I lifted my SC including the manifold to see if the blue hose under the manifold was the cause of my idling problem.

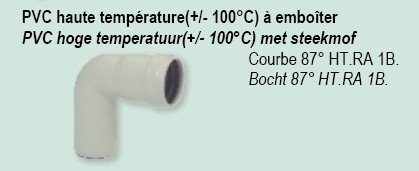

Mark Basch was right. The blue hose under my SC was broken. A vacuum leak as a result.

Here are some pictures of the trouble maker:

This is the thread I started with:

idling problem

This morning, with the help of Cees-Jan, I lifted my SC including the manifold to see if the blue hose under the manifold was the cause of my idling problem.

Mark Basch was right. The blue hose under my SC was broken. A vacuum leak as a result.

Here are some pictures of the trouble maker: