Questions/comments from a guy in the middle of the TB replacement job.

1) I find that 3/16 and 13/64" drill bits fit perfectly in to hold the cams in position. They slide through the cam retainer whole easily, then bottom out in the holes in the cam after about 1/8". So far so good.

2) There is a lot of stuff to take off. For instance, almost every wire harness bracket bolt on the passenger side has been removed to make this easier. It will be interesting to see if I notice all of them needing to be replaced.

3) My crank bolt was as stuck as I assumed it was. My cheap impact gun did nothing. But, a standard 15" breaker bar, 1/2" drive, with a small cheater bar (a jack handle) did it. At first try, my breaker bar started bending. So I then added the cheater bar and put a floor mat over it in case it snapped. I heard the loud "crack", then inspected stuff to see what broke. It was just the bolt coming out. I'd say I was about 20" away so total torque was less than 330 foot lbs.

Questions...

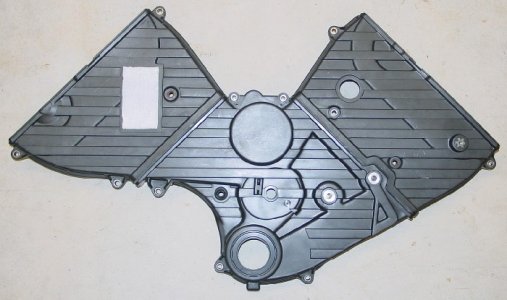

1) I had a heck of a time getting the covers off. I had the jack lifting the engine from the front more than from the side. The jack was reaching in from under the door instead of being under the rotor. I could only get the engine to tilt so far before the oil cooler got wedged under there (I presume between engine and suspension). There is pretty much no way that I'm going to be able to get the covers back on and bolts in with this limited access. If I jack from the side, coming from under rotor instead of under door - is that the ticket? Or, should I remove the oil cooler and pedestal? Or both?

Also, I removed the tranny bolt completely. The engine is still held by the front and rear brackets. Would it help to put the tranny bolt back in?

2) I am not sure I know which pulley is the crank pulley - the one that fails. I have the A/C and alternator (double) pulley off. Is that the one that fails? Or, is it the one that actually turns the timing belt? And, if it is the little one that turns the timing belt, why does it cost over $200? And, is there any special procedure for getting it off?

Next up:

o mark, then remove timing belt (looks perfect btw)

o replace water pump

o replace crank pulley (once I buy one)

o swap leaking cam seals (if I can find the leaks)

o re-install is reverse of disassembly

So far so good, but I'm nervous about getting these timing covers back on.

Thanks for any advice.