Wondering if anyone can help...

I recently upgraded my wheels and I now have an 8mm Ring on the rears. So to be on the safe side I ordered longer studs for an extra 5.5mm longer over stock.

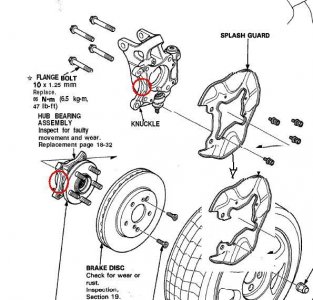

Problem I'm having is, I can easily remove the wheel studs, but they get caught between the hub base. Anyone know what needs to be done to remove the studs? I think I have to disassemble the hib assy into its 2 pieces then able to remove the studs?

Thanks,

I recently upgraded my wheels and I now have an 8mm Ring on the rears. So to be on the safe side I ordered longer studs for an extra 5.5mm longer over stock.

Problem I'm having is, I can easily remove the wheel studs, but they get caught between the hub base. Anyone know what needs to be done to remove the studs? I think I have to disassemble the hib assy into its 2 pieces then able to remove the studs?

Thanks,