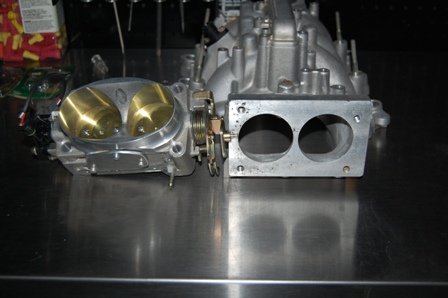

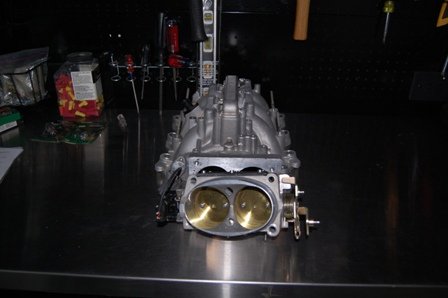

Kaz tested big bore throttle bodies for NSXs. He mentioned what he found here:

http://www.nsxcb.co.uk/showthread.php?10146-B-line-motorsports&p=94119#post94119

In a nutshell: a bored-out throttle body can increase an NA2’s power but not a mildly-modified NA1’s. If vendors claim differently, I assume it’s just marketing hype.

If we look to GT-ONE bbtb+tune, they claim that power increased from 268 to 304 ps in a mild tuned AT car (not sure but i think they state only Exhaust...) and the rev limit was increased to 8000 rpm for the AT... but i agree that this could be just marketing hype. And kas is really the guy to trust on this matter...:wink:

using those formulas 74mm TB can theoretically deliver 316whp and 363 engine hp

316whp and 363 engine hp should be enough for me, especially if we could achieve this number without opening the engine :biggrin: :biggrin: :biggrin: