Early ABS modulator servicing

- Thread starter OLDMNSX

- Start date

Brad, thanks for taking on this challenge. Like Briank and his amp/climate control service, it sounds like you are on the way to becoming another wonderful resource (ABS) for the NSX brothers (and sisters).

thanks again

Bill

Thanks Bill,

I hope that to be the case, I still have some experimenting to do with some of my test equipment that I am building. I am sitting in my hotel room in Aurora CO looking at my plan to lay out the switches and indicator lights on the ABS test box that I hope to get put together this weekend when I get home. I figure that if I had to take my car to the dealer to flush the ABS twice and I still have a problem that there are others out there. They may not want to go through what I am to fix the problem and have just left it non-functional. That is who I want to help.

Brad

Hey Brad,

I got a chance today to service the ABS.

I have the Honda purge / flush tool.

Ran the pump <20 sec at at time.

Completely replaced all the fluid. First from the top then flush through new clean fluid.

I exersized the modulators one at a time with the pump running.

Result is a lot of bubbled foamy Brake fluid removed.

Removed again through the top and then flushed new fluid through the system to the bleed service hole.

Everything worked as per the manual and Dali Racing help pages.

http://www.daliracing.com/v666-5/info/article_read.cfm?articleID=826

I am concerned about the sound of my ABS pump though. It is quite loud. It has kind of a squealing sound at times. Is this normal, or do I need a new ABS pump?

Thanks again for all the great help and coaching.

This is really a simple exersize. Took an hour with taking my time through the way.

I got a chance today to service the ABS.

I have the Honda purge / flush tool.

Ran the pump <20 sec at at time.

Completely replaced all the fluid. First from the top then flush through new clean fluid.

I exersized the modulators one at a time with the pump running.

Result is a lot of bubbled foamy Brake fluid removed.

Removed again through the top and then flushed new fluid through the system to the bleed service hole.

Everything worked as per the manual and Dali Racing help pages.

http://www.daliracing.com/v666-5/info/article_read.cfm?articleID=826

I am concerned about the sound of my ABS pump though. It is quite loud. It has kind of a squealing sound at times. Is this normal, or do I need a new ABS pump?

Thanks again for all the great help and coaching.

This is really a simple exersize. Took an hour with taking my time through the way.

>are you saying that the motor can be removed from the pump on the car?

That IS what I am saying, yes.

> (leaving the pump connected to the ABS.) I have a parts breakout diagram that shows the pump/motor as one assembly, but there are screws/bolts attaching them together.

1. You didn't look very hard.

2. You live in the USA. Well, then liability exposure has HNA scared...so they only show it as a single assembly.

3. If you look just a bit harder, you will find interesting things. I'm trying to get a copy of the EU Service Manual, it goes over ALB servicing in detail.

4. I just make this stuff up, see here

http://www.nsxprime.com/forums/showp...00&postcount=7

http://www.nsxprime.com/forums/showthread.php?t=93863

(maybe not)

>I priced out the pump. the best price I could find is $350.00USD from Dali.

I have the parts interchange for the pump...it is on several cars: vigor, legend and a couple of others.

Thanks Drew.

The bolts are actually accesable in the car! I was going to remove the three legged mounting bracket out as well. Over the years the brake fluid has removed the paint.

A little lithium grease should do the job and make the pump a little less noisey.

That IS what I am saying, yes.

> (leaving the pump connected to the ABS.) I have a parts breakout diagram that shows the pump/motor as one assembly, but there are screws/bolts attaching them together.

1. You didn't look very hard.

2. You live in the USA. Well, then liability exposure has HNA scared...so they only show it as a single assembly.

3. If you look just a bit harder, you will find interesting things. I'm trying to get a copy of the EU Service Manual, it goes over ALB servicing in detail.

4. I just make this stuff up, see here

http://www.nsxprime.com/forums/showp...00&postcount=7

http://www.nsxprime.com/forums/showthread.php?t=93863

(maybe not)

>I priced out the pump. the best price I could find is $350.00USD from Dali.

I have the parts interchange for the pump...it is on several cars: vigor, legend and a couple of others.

Thanks Drew.

The bolts are actually accesable in the car! I was going to remove the three legged mounting bracket out as well. Over the years the brake fluid has removed the paint.

A little lithium grease should do the job and make the pump a little less noisey.

Warren,

I have an extra pump if you want to try it and see if you notice any difference. I think that you may still have some air in the fluid. Drop me a PM.

Brad

I have an extra pump if you want to try it and see if you notice any difference. I think that you may still have some air in the fluid. Drop me a PM.

Brad

Just another little tid bit of info on this journey of discovery of the NSX ABS system. I have been courious as to what is the normal system pressure, i.e. what pressure closes the pressure switch on the accumulator adapter.

I had a hose made up to be able to do this. I took the switch attached to the switch to the aircraft hangar and found the nitrogen bottle. I hooked it all up and started to increase the pressure. I had my multi-meter attached to the pressure switch connector. Up and up goes the pressure, monitoring the Ohm meter looking for continuity. Well I got to the max pressure in the bottle and still no connection in the pressure switch. The nitrogen bottle had 2800 psi on board! So, our ABS system operates at over 2800 psi pressure.

Is there anyone out there that knows the exact operating pressure, if so please let us know. I have two other switches that I will also test to see if the one that I was using is defective.

Brad

I had a hose made up to be able to do this. I took the switch attached to the switch to the aircraft hangar and found the nitrogen bottle. I hooked it all up and started to increase the pressure. I had my multi-meter attached to the pressure switch connector. Up and up goes the pressure, monitoring the Ohm meter looking for continuity. Well I got to the max pressure in the bottle and still no connection in the pressure switch. The nitrogen bottle had 2800 psi on board! So, our ABS system operates at over 2800 psi pressure.

Is there anyone out there that knows the exact operating pressure, if so please let us know. I have two other switches that I will also test to see if the one that I was using is defective.

Brad

Warren,

I have an extra pump if you want to try it and see if you notice any difference. I think that you may still have some air in the fluid. Drop me a PM.

Brad

thanks for the offer Brad.

My car is still in storage. I am going to get it out and drive it shortly. That will be the true test. I agree that there still may be some air in the system. I ran about 1 litre of new DOT 4 fluid through the pump. Filled the Acumilator. It squeels when the pump first starts, but is more quiet once it has run for about 3 or 4 seconds.

I will take you up on your offer if required.

As well the motor can be removed from the pump mechanisim. Some lithium grease may do the trick.

I will up date with more info.....

Well, I got a gauge put in between the pump and the modulator unit. I started the car (up on jacks) and put it in 3rd gear, pump started to kick in, I was watching the gauge and it started to increase in pressure to the point it was bouncing over 5000 psi, the max for the gauge was 5000 psi. I immediately turned it off. I think I need an oil filled gauge that goes to 8 or 9000 psi to get an accurate reading. We may have an answer next week.

Brad

Brad

OK guys I was finally able to get a pressure reading on the ABS system. When the OEM maintnenace manual says that the ABS system operates at HI PRESSURE, they were not kidding.

With the right fittings and gauge I was able to find out. Normal operating pressure is 4800 psi. When the pressure decreases down to 2800 psi the pump turns on. When the system was cycling I saw a max pressure of 5400 psi momentarily. I was able to get one of my solenoids to leak to get the system to cycle pressure up and down to get the pump on and pump off pressures. I took a few still pictures and also a video clip.

Brad

With the right fittings and gauge I was able to find out. Normal operating pressure is 4800 psi. When the pressure decreases down to 2800 psi the pump turns on. When the system was cycling I saw a max pressure of 5400 psi momentarily. I was able to get one of my solenoids to leak to get the system to cycle pressure up and down to get the pump on and pump off pressures. I took a few still pictures and also a video clip.

Brad

Attachments

Hey Brad,

what triggers the pump?

obviously the presure switch; but is it a speed sensor as well..

Also what triggers the idiot light on the dash. Is it just the presure switch?

Today I was able to get my car out of storage.

The presure was down on the ABS, I had to jump the relay contacts to get the presure up. I may have a bad relay.

what triggers the pump?

obviously the presure switch; but is it a speed sensor as well..

Also what triggers the idiot light on the dash. Is it just the presure switch?

Today I was able to get my car out of storage.

The presure was down on the ABS, I had to jump the relay contacts to get the presure up. I may have a bad relay.

Hey Brad,

what triggers the pump?

obviously the presure switch; but is it a speed sensor as well...

Warren, the pump is controlled by the ABS ECU with inputs from a speed sensor and the pressure switch. The rear wheels have to be turning greater than 10 k/hr or about 6 mph. The pressure switch has to show "Open", or low, on pressure to allow the pump to engage. Remember that the pressure switch only gives the ECU an open or closed indication. If you think about it, it works backwards. When the switch shows open, or low on pressure, this is when the pump is "ON". This is because it works through the ECU.

Also what triggers the idiot light on the dash. Is it just the presure switch?...

No, the light is controlled by the ECU and will illuminate the light for a number of reasons. One of them is if there is a component that is not connected, like a solenoid. I learned that the hard way. I was trying to get the system to control the operation of the pump and I wanted to control one of the solenoids. I couldn't get the pump to activate and with the solenoid disconnected and I could not get the ABS fail light to extinguish. Learn as you go.

Today I was able to get my car out of storage.

The presure was down on the ABS, I had to jump the relay contacts to get the presure up. I may have a bad relay.

Were the rear tires turning at 6 mph or greater? If not, give that a try. It should activate the pump, the question is, how often will it activate the pump.

Brad

Warren, the pump is controlled by the ABS ECU with inputs from a speed sensor and the pressure switch. The rear wheels have to be turning greater than 10 k/hr or about 6 mph. The pressure switch has to show "Open", or low, on pressure to allow the pump to engage. Remember that the pressure switch only gives the ECU an open or closed indication. If you think about it, it works backwards. When the switch shows open, or low on pressure, this is when the pump is "ON". This is because it works through the ECU.

No, the light is controlled by the ECU and will illuminate the light for a number of reasons. One of them is if there is a component that is not connected, like a solenoid. I learned that the hard way. I was trying to get the system to control the operation of the pump and I wanted to control one of the solenoids. I couldn't get the pump to activate and with the solenoid disconnected and I could not get the ABS fail light to extinguish. Learn as you go.

Were the rear tires turning at 6 mph or greater? If not, give that a try. It should activate the pump, the question is, how often will it activate the pump.

Brad

Thanks again Brad:

I did take it for a ride more than 6 mph.

I found a solenoid with a bad connection. (left from my exersising the solenoids)

I also learned that you have to re-start the car to clear the fault light.

This made the troubleshooting process more complex. Once I had the presure up, it has stayed up and the pump hasn't had to pump since yesterday.

It is parked for a while as I will be out of town for a week. I will see if the pump needs to run once I return.

I am sure that all the knowledge I have gained working on this ABS system will pay off for years to come. :wink:

thanks again.

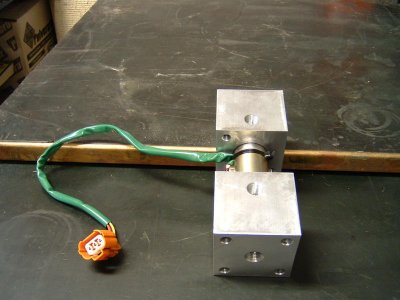

Well it was like Christmas morning yesterday. Santa Claus showed up with the blocks that I ordered mid December 07. These were the one part that I was not physically able to manufacture (economically) to accomplish this goal that I have made to fix these early ABS systems......I think........I hope.

As you look at these aluminum blocks you will see tapped holes in the sides and the one end. These will have fittings installed that will allow me to push fluid into the solenoid in a reverse flow from normal. This will flush any particles out of the solenoid in an effort to get them to stop seeping under the 4800 psi pressure. The solenoid that you see here has a nipple on the top and bottom. The nipple on the top is used to attach the manifold that provides mounting for the reservoir. The bottom nipple is where the HI pressure fluid enters under normal operations. You can also see the very fine screen where the fluid passes to return to the reservoir.

Stay tuned there is more to come.............be patient...........

Brad

As you look at these aluminum blocks you will see tapped holes in the sides and the one end. These will have fittings installed that will allow me to push fluid into the solenoid in a reverse flow from normal. This will flush any particles out of the solenoid in an effort to get them to stop seeping under the 4800 psi pressure. The solenoid that you see here has a nipple on the top and bottom. The nipple on the top is used to attach the manifold that provides mounting for the reservoir. The bottom nipple is where the HI pressure fluid enters under normal operations. You can also see the very fine screen where the fluid passes to return to the reservoir.

Stay tuned there is more to come.............be patient...........

Brad

Attachments

Very cool Brad. You gonna make a flushing rig?

The normally open (N.O.) switch is a fail safe to ensure you have ALB pressure. Otherwise it would be difficult to determine if you have a catastrophic failure...

If you think about it, it works backwards. When the switch shows open, or low on pressure, this is when the pump is "ON". This is because it works through the ECU.

The normally open (N.O.) switch is a fail safe to ensure you have ALB pressure. Otherwise it would be difficult to determine if you have a catastrophic failure...

MvM,

From what you have told us it sounds like you drive your car at the far extreme of the capabilities of the 94's ABS.

In order to flush your current ABS system you will need a Honda T-Handle bleeder tool and will have to look up the ABS DIY that was done by DanO and make up the wiring harness to cycle the solenoids. Do a search for ABS and it should show up. The solenoids on the 93-99 ABS are a little different from the 91-92 ABS, but they do the same thing. I recently received a 93 ABS modulator unit and haven't had time to disassemble it to see the differences.

Brad

Hi Brad,

This is a short post in your own thread to let you know how things worked out.

First of all, I replaced the Racing Brake rotors with new ones and this time went to the Hawk HPS pads in front. Their bite is a bit less than the HP+ but I have already noticed that they dust much less than the HP+ pads.

Second, I flushed both the ABS and brake system. Used the solenoid-procedure from danoland.com. I had trouble with the rear left solenoid (second row, right connector). It would click, but no fluid was coming out. So I flushed the other three channels.

Then someone here suggested that I would alternate between the ABS-pump switch and the solenoid switch quickly. After about two minutes of doing that, the solenoid would finally open and the fluid come out. So I refreshed that fluid also.

After that it turned out I had damaged a brake line during the rotor replacement, but after that was fixed the brakes seem to work again like before. They saw some heavy using during a trip in the Ardennes and although I did experience some fade during a few rapid descents due to the brakes getting very hot, the system otherwise functioned fine.

So, thank you very much for your advise. I've learned some useful things about the car again.

Similar threads

- Replies

- 45

- Views

- 2K