I have a 92 with the AEM FIC and got it tuned today. This is the odb1 car runs great but when I go into boost the TCS light comes on. Does not matter if TCS is off or on the TCS light will come on solid shortly after going into boost. If I just rev the engine without load thus no boost it does not get the TCS light. Any ideas? Does the TCS light prevent the engine from going into vtec just curious was thinking about this on the drive home from the tuner since I made about 15-25 hp short of what I expected. Came out with 361 rwhp with 6.6 lbs of boost at around 7300 rpm. Guess that last 15-25 hp could be in the last 700 rpm or so but the tuner did not want to bounce off the rev limiter.

AEM FIC with TCS light on

- Thread starter Jhouser

- Start date

My guess is that the voltage clamp on the MAP sensor is set too low, though i'm not sure why the CEL didn't come on along with the TCS light. If the OEM MAP sensor see's too much voltage it wasn't expecting (i.e. boost) it will throw a CEL iirc. You can try incrementally adjusting the voltage clamp and see how that goes.

Again, not sure why the CEL didn't come on either if indeed this is a MAP sensor problem.

Other "usual suspects"... is the tire size and in extreme cases tire air pressure.

$0.02

- - - Updated - - -

btw.. what dyno?

Again, not sure why the CEL didn't come on either if indeed this is a MAP sensor problem.

Other "usual suspects"... is the tire size and in extreme cases tire air pressure.

$0.02

- - - Updated - - -

btw.. what dyno?

TCS does not actually kick on just the TCS light comes on like it needs service. No check engine light. If I stay out of boost the TCS light never comes on so definitely something to do with the boost. When the light comes on it comes on and stays on solid until i turn off car. It is not like when i lose traction and feel the brakes or engine cut out and see the light just flash momentarily then everything is normal. Tire pressure is good and tires have been on for more than a year and in good shape with no past problems.

The dyno was the Dynapack 3000

The dyno was the Dynapack 3000

Your tuner is a dork for not pulling to 8k. That's what you pay him for. Otherwise how can he check your AFR at that point? Anyhow, how does the car feel? What was your torque number?

6.6tlbs of boost netting 361 rwhp is a great because you get awesome hp without stressing the motor too much. Your last 700 rpm's will net another 20hp.

What was your AFR at wide open throughout the rev range? Should be 11.5 to 11.9 or so.

I hope you made over 300ft lbs of torque or else your tuner left a lot on the table.

You could always pull your tcs fuse temporarily and there are a lot of threads dealing with that if you use search.

6.6tlbs of boost netting 361 rwhp is a great because you get awesome hp without stressing the motor too much. Your last 700 rpm's will net another 20hp.

What was your AFR at wide open throughout the rev range? Should be 11.5 to 11.9 or so.

I hope you made over 300ft lbs of torque or else your tuner left a lot on the table.

You could always pull your tcs fuse temporarily and there are a lot of threads dealing with that if you use search.

Last edited:

My peak torque is 259 at 7150 and hp is 361 at 7500 which is where he stopped not the 7300 I previous said. Tuner said that since he could not easily stay off the stock ecu rev limiter he was more comfortable not pushing it. I didn't ask more on it he seemed to elude that if I had the aem ems that you can easily set up the pulls to redline on the ems and it is either programmed or potentially not as hard on the engine ie it does not cut fuel maybe? I did not press for info on this but did not want him to push it to get those last 500 rpm on the dyno as long as he thought he had the map setup fine for the afr which he said he felt was fine.

This is on a bbsc not a turbo engine. The bbsc dyno graphs I have looked at all seem to have torque numbers under 300.

Car runs great all the way up up to 8k. Afr at wide open is right around 11.5 to 12. Car drives just like stock when not in boost and when hitting the gas the boost is very smooth due to the slow spin up of the supercharger.

This is on a bbsc not a turbo engine. The bbsc dyno graphs I have looked at all seem to have torque numbers under 300.

Car runs great all the way up up to 8k. Afr at wide open is right around 11.5 to 12. Car drives just like stock when not in boost and when hitting the gas the boost is very smooth due to the slow spin up of the supercharger.

My peak torque is 259 at 7150 and hp is 361 at 7500 which is where he stopped not the 7300 I previous said. Tuner said that since he could not easily stay off the stock ecu rev limiter he was more comfortable not pushing it. I didn't ask more on it he seemed to elude that if I had the aem ems that you can easily set up the pulls to redline on the ems and it is either programmed or potentially not as hard on the engine ie it does not cut fuel maybe? I did not press for info on this but did not want him to push it to get those last 500 rpm on the dyno as long as he thought he had the map setup fine for the afr which he said he felt was fine.

This is on a bbsc not a turbo engine. The bbsc dyno graphs I have looked at all seem to have torque numbers under 300.

Car runs great all the way up up to 8k. Afr at wide open is right around 11.5 to 12. Car drives just like stock when not in boost and when hitting the gas the boost is very smooth due to the slow spin up of the supercharger.

I have hit rev limiter plenty of times with FICs on NSXs both turbo and FI. A blip or two of the rev limit isn't going to hurt anything on the engine. I know dynapacks are a bit more harsh on the driveline because there is no give to the hardware. All the shock and vibration are put into the driveline and ultimately the engine. There isn't a roller or tires to absorb most of it. Still, not a reason to avoid going near the limiter. Plus, the Dynapack can stop the engine from rotating beyond a specific RPM if the tuner wants it to (ex 8000rpm) so it won't hit the limiter. As far as the TC light, check the wiring. Was it hard wired or is there a jumper PnP harness involved? As a rule of thumb for tuning without any kind of aftercooler or even with on those engines you want to be more fat in the fuel curve than a 12.0:1 AFR. I would consider it added insurance for the long term. Hope this helps.

Does the F/IC have a IAT compensation map? I don't recall off hand. If it does, it would be wise to add more fuel gradually at the upper RPMs as the IATs go up. 12's does seem a tad on the high side. Are you measuring at the tailpipe or before the cats? It's when you get the most power though so it depends on your Kaboom comfort level

Also, Dynapacks tend to have the highest variances between them. The loading can also be weird. If you have the option to use a Superflow, Mustang, or Dynojet I think you might get different results. In any case, dynos are used to tune under load. I think whatever #'s you end up is sort of arbitrary by itself. It's the delta that's important. Anyway, i'm sure you guys already know this. At least you don't have to deal with CRAP California gas like we do.

I'm sorry I can't offer more help on your TCS issue. I still think it's worth checking the MAP voltage clamp. Mine was around ~3Volts IIRC. Also, if it was my car I would want to see the data once rev limiter is hit. You're going to hit that on the street once in a while, even if by accident, so it's good to try to recreate all conditions via the dyno.

Also, Dynapacks tend to have the highest variances between them. The loading can also be weird. If you have the option to use a Superflow, Mustang, or Dynojet I think you might get different results. In any case, dynos are used to tune under load. I think whatever #'s you end up is sort of arbitrary by itself. It's the delta that's important. Anyway, i'm sure you guys already know this. At least you don't have to deal with CRAP California gas like we do.

I'm sorry I can't offer more help on your TCS issue. I still think it's worth checking the MAP voltage clamp. Mine was around ~3Volts IIRC. Also, if it was my car I would want to see the data once rev limiter is hit. You're going to hit that on the street once in a while, even if by accident, so it's good to try to recreate all conditions via the dyno.

Last edited:

Have you tried pulling the TCS codes to see if there is indeed an issue that is being recorded?

My guess, based on its relation to boost, would be the voltage clamp as well; but I had one fail on me many years ago and not only did it trigger the Check Engine light (can't remember if it triggered the TCS light), but it also put my car into limp mode every time I hit boost. Since you're not experiencing this symptom, I'm wondering if it could actually be directly related to your TCS.

My guess, based on its relation to boost, would be the voltage clamp as well; but I had one fail on me many years ago and not only did it trigger the Check Engine light (can't remember if it triggered the TCS light), but it also put my car into limp mode every time I hit boost. Since you're not experiencing this symptom, I'm wondering if it could actually be directly related to your TCS.

I checked the TCS code and got back 5.1 abnormal fail safe relay, throttle actuator or throttle body. Possible causes are failsafe relay, throttle actuator, throttle body, wire harness, or TCS control unit. Checked all wire harness and all seated. Not really near where I worked. Never had TCS issues prior to bbsc install. I did install the fuel pump wire kit and new walbro at the same time as bbsc. Only get the TCS light on when I go into boost and happens every time. I did notice once today that father I turned and tried to hit the gas no acceleration until I let off the gas a bit then hit it again seemed to be the TCS engaged even though solid TCS light. Thinking about unplugging TCS module and making sure I don't have that issue with it out of the system.

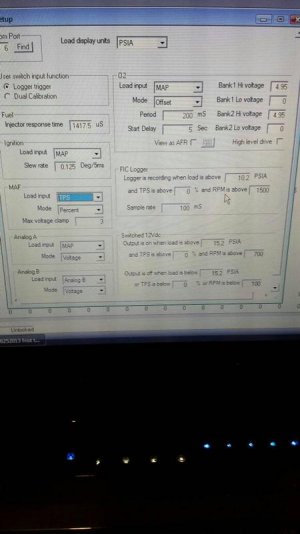

How is the FIC wired? Is it a PNP jumper harness or hard wired? Your MAF load input should be set to MAP. Also, the map clamp voltage is too high. 2.85-2.89V will do the trick. After these settings make sure the tune isn't off.

Last edited:

The fic is wired with the jumper harness. I can make the changes to the maf load input and the clamp voltage. How do I make sure that the tune isn't off? I did not see a place to turn it off or onion the programming.

The fic is wired with the jumper harness. I can make the changes to the maf load input and the clamp voltage. How do I make sure that the tune isn't off? I did not see a place to turn it off or onion the programming.

I didn't mean off as in on/off selection in the programming. I meant make sure the AFRs don't change from where they were when it was initially tuned. I recommend another dyno session if you don't have access to at least a wideband.

Made the changes dmscrx recommended. Clamp at 2.89 and maf load input to map. Tune still looks the same afr looks unchanged but still getting TCS light coming on. Did some checks and TCS comes on around 2.5 to 3 lbs of boost. Always comes on. I did reset the TCS after making the change so not sure what to try next.

Thanks

james

Thanks

james

Last edited:

How is the FIC wired? Is it a PNP jumper harness or hard wired? Your MAF load input should be set to MAP. Also, the map clamp voltage is too high. 2.85-2.89V will do the trick. After these settings make sure the tune isn't off.

Take heed of this advice, the voltage clamp has an effect on WOT fuel and peak timing. This car should be back on the dyno for a propper tune. I have used 2.93 as my clamp voltage for years with out issue. Also are you using the 12vdc output from the F/IC? If not then the settings should be "0" in all fields and the wire should be terminated to prevent a short.

Also are the OEM O2 sensors wired into the F/IC harness, if so you have some issues with the cal setup for the O2's, if not it does not matter.

Also you are using the older software and firmware, there is a newer version available than what you have now. The new version has a Fuel Accel Pump Feature that can be usefull if you are having tip in fuel issues.

As far as your rev limmiter, I am not sure on the OBDI cars if the limiter is a fuel cut or an ignition cut. It is however a soft cut untill you hit about 8200 rpms. If you plan to hit 8000 RPMs on the street the car needs to be tuned to 8000 so you know it is safe. With Dynapacks you can configuer your sample and define the run to stop at 7950RPM and you will have to get out of the run ASAP to avoid going much over 8000 rpm.

Dave

I am using a jumper harness I think that is from SOS.

Is there a problem with having the clamp at 3 as it was?

i am not using the 12vdc output from the fic I will check to see where this wire is on the harness but I think it has heat shrink on it still.

I am not using the oem o2 sensors wired to the aem fic.

I do have the z110 firmware which is what aem recommended for the nsx do you know what newer rev is? I will look for the newer software but I downloaded that from the website last week so thought it was the newest.

Dave any clue why I am getting the TCS light?

Thanks again for all the help. Trying to learn as I go so I understand what everything means.

James

Is there a problem with having the clamp at 3 as it was?

i am not using the 12vdc output from the fic I will check to see where this wire is on the harness but I think it has heat shrink on it still.

I am not using the oem o2 sensors wired to the aem fic.

I do have the z110 firmware which is what aem recommended for the nsx do you know what newer rev is? I will look for the newer software but I downloaded that from the website last week so thought it was the newest.

Dave any clue why I am getting the TCS light?

Thanks again for all the help. Trying to learn as I go so I understand what everything means.

James

Is there a problem with having the clamp at 3 as it was?

I am not using the oem o2 sensors wired to the aem fic.

I do have the z110 firmware which is what aem recommended for the nsx do you know what newer rev is? I will look for the newer software but I downloaded that from the website last week so thought it was the newest.

Dave any clue why I am getting the TCS light?

Thanks again for all the help. Trying to learn as I go so I understand what everything means.

James

If the OEM ECU ever receives 3.0+VDC it may go into limp mode. The F/IC voltage clamp will waver from time to time, you can log the MAP voltage in and out to make sure it does not change. I will go back and look at some old dyno logs and see if the OBDII data I have collected shows a change in timing if the voltage increases higher than my normal clamp voltage of 2.93.

There is firmware and software, you are using the older software, there is a newer version available. The z110 firmware is for the fuel strategy and should not be changed, there is also another piece of firmware in the F/IC that corresponds to the software version you use. You can get the new version of software and the corresponding firmware from the AEMPower Forum under F/IC.

If I had to guess about your TCS issue I would say something is not wired correctly in the harness, since the light only comes on in boost it will be hard to simulate and diag.

Is this a CTSC or Turbo car?

Dave

This is a BBSC car. I will check all the connection again. To disable the TCS can I just unplug the TCS module behind the drivers seat? I may just do that and then hold off until I do a few more mods before going to a aem series 2 stand alone.

Thanks

james

Thanks

james

Similar threads

- Replies

- 45

- Views

- 2K

- Replies

- 29

- Views

- 850

- Replies

- 0

- Views

- 81