Re: ABS conversion wiring & more

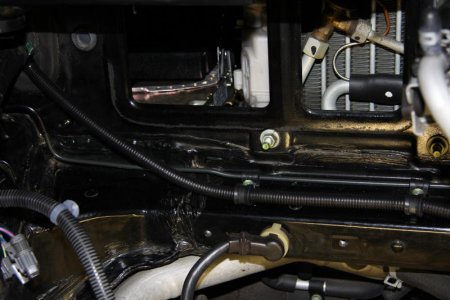

If you already have decided to do this, the following may be of interest in addition to the SOS installation instructions that comes with their harness: Pull the heater assembly for better access.

Tks Tanto .. great advice .. I just did this conversion in the last week and your advice made it much easier access to work with the firewall grommet

The worst part of the install is replacing both front brake lines to the calipers.

Actually, I'm not convinced it was the worst part but it's right up there. In fact, after doing the front left line, I had a long hard look at whether I couldn't just re-bend the right line to reach .. and it wasn't that hard to do. But in retrospect I don't think I could have re-bent the left one. My other candidate for "worst part" would be the removal of the cradle that holds the old ABS computer .. way too many other electrical plugs to disconnect in a space half the size it needs to be.

I did wire the harness considerably simpler than SOS instructions show.

I just used those crushable (STAKON?) connectors that already have an insulated coating on them and then used electrical tape to finish up. But on the topic of the harness, the SOS instructions say to install the harness first and one of the first steps is to locate the pump power connector. It must have taken me a least a half an hour to find it because the picture they supply is of all the other connectors. I decided to do the harness after swapping the ABS hardware and then all the connectors were much more obvious and easy to deal with.

I could probably do this job a second time in a very long day, but I would allow several days for this job. It is a bit confusing the first time.

You've got to be kidding! I'm no mechanic but I'm pretty handy and have a reasonable selection of tools but it took me 3 elapsed days although I wasn't working on it full time. I think it took me about 12 hours just to disassembly the glove box and remove the old abs computer; run the wiring harness (including removing and replacing the blower); replace the abs bracket and make the connections; re-assemble the glove box; bleed the brakes; and fix a leak in one of the ABS hard lines (I hadn't tightened it enough). When I first read the SOS instructions that say something to the effect of "remove the cradle that holds the old ABS computer and other electronic assemblies", it sounded like much more of a cake-walk than it turned out to be. To their credit, they supply everything (parts) in the kit that you'll need; everything fit first time; and they do have pictures with the instructions that did help.

This actually brings up a strong recommendation I have .. when buying the flare nut wrench for the brake line connections (10 mm BTW), try to get one that has a joint at one end. Once you start getting the lines installed, there is virtually no room to work on some of them (because of the brake cylinder and all the bends) and I'm not sure I could have done it without a flexible flare nut wrench.

A couple of times when I started to get frustrated with things, I thought "this definitely isn't for the average 'do-it-yourselfer' but looking back, I think that with some revisions to the SOS instructions .. and advice from yourself and others .. plus a shop manual is an advantage as well .. I think it probably could qualify as a DIY project as long as this isn't your first trip under the hood and you are methodical and don't frustrate easily. And if I'm any example, you're going to wind up with lots of brake fluid on your garage floor so try to take precautions.