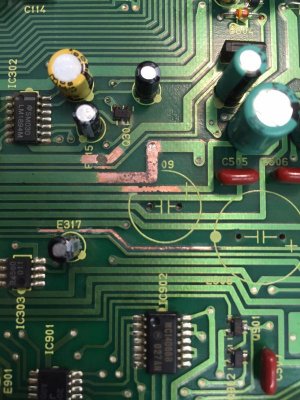

I think, I found my problem. Capacitors are ordered. We'll see how it goes.

No surprise.

If you are an electronics whiz and know how to sling a soldering pencil, you can ignore the following. If not, then the following comments may be helpful in providing a successful outcome:

- Do not use a soldering gun, too much heat. Use a 25 watt fine tip soldering iron / pencil for installation of the parts.

- A solder vac hand tool can assist in the removal of the old capacitors and clean up of excess solder.

- The circuit board will have a conformal coating applied on it to protect the solder and traces. Depending on the type of conformal coating, it can be removed with the appropriate solvent; however, some conformal coatings need mechanical removal. The conformal coating at the repair point should be destroyed in the de soldering process. Use a tooth brush to clean off residue. If the solder repair goes well, you probably don't have to do anything more in terms of removing the existing coating. If you find that you are having trouble getting a nice clean solder repair, you may have to clean the repair location surface to remove any residual conformal coating. Look up removing conformal coating on the web. It can range from easy to messy depending on what the original manufacturer used to coat the board. Here is hoping that it is not an issue!

- There are circuit board cleaners or you could use an electronic contact cleaner to help remove the capacitor residue.

- Solder in new parts using a resin core solder. Solder for use in electronics comes in different diameters. Try and get 22 gauge (.032 ") as the amount of solder deposited is smaller and it makes soldering on a PC board easier if the spacing between the traces is fine (bridging traces - bad thing).

- After completion of all the solder repairs, clean the circuit board repair locations with flux remover.

- After cleaning the board, spray with a conformal coating (I like the acrylic versions of conformal coatings).

The conformal coating is important in terms of preventing corrosion and bloom on the circuit board if you want a long lasting repair.

I, as probably other owners look forward with interest to your repair results.

Edit:

Looking at the photo, it almost looks like one of the traces next to the 1000 uF capacitor is lifting. Be careful when cleaning that you don't lift or tear the trace. You may have to confirm that the trace is intact and making contact with whatever it should. If the trace is not badly lifted, the confomal coating may be sufficient to hold it in place and prevent further problems. If it is badly lifted, you may have to explore repair options (something that I have never had to do).

Also, next to the lettering E315 on the board there looks to be a black spot that looks like burning on the trace. You may need to examine that and make sure that the trace is intact. If the capacitors shorted out when they failed there may be collateral damage on the board in addition to just the failed capacitors. Check the board over carefully.