Ok, since I have an upcoming chassis setup appointment, I decided to spend some time on chassis setup playing in the garage (up and down and up down on jack stands to calculate CG, etc... and experiment around. There is a Audi Club event I registered to help out with in two weeks.. I'm hoping to use as a test and tune day (since it will probably pour down rain being one of the last days of the year it should be fun).

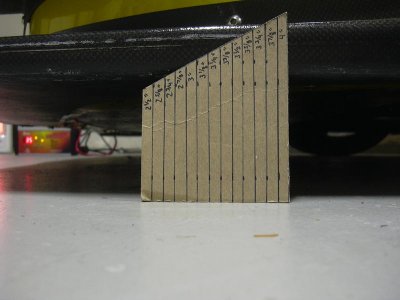

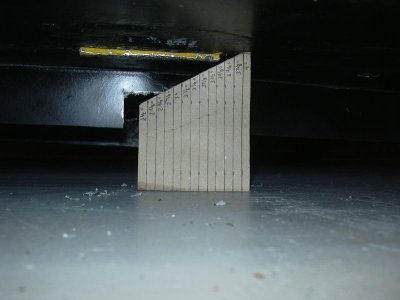

First, as can be seen a relatively aggressive ride height that should make getting it onto a trailer interesting to say the least. I could probably go a little lower, but definitely not under 3" without trimming the fenders and liners, and swapping a few things around as under track load I'd probably rub.

Below is a close up to the jack tab. As long as you are bringing your own gas... I think 3.5-3.75 would probably get the job done. Maybe not the 50mm of JGTC or DTM, but you know for the club red line time attack stuff; from what I've seen of other race touring prepared style cars.. compared to Crawford, Matrix, GST, etc... if you aren't otherwise limited by rules this would probably be a pretty freakin' aggressive start.

With the new seating position (as low and far back as I could get it) my butt is essentially under the center line of the hub. All I know is that the highest point on the car is the rear wing at like 45-46" off the ground which means the BMW sedan in front of me looks like some kind of monster truck. :biggrin:

Now, you can see the effect on the rear lower A Arm. Relative to "street height" you can see how drastic an effect lowering has on the geometry. It's not linear, going from an 1.25" under stock to 1.85" under stock on the jack tab has a significant effect as the arm pivots. From a couple of degrees to what you see here which is probably closer to 25-30 degrees. I probably would need a little over an inch to set that rear arm level again. The front is harder to ascertain but appears similar to me... so the front roll couple to rear ratio roll couple is likely similar; which suggests that all four hubs could benefit from an adjustable RCA.

I have some free chassis setup software and am going to throw a few hours at this today and see where I arrive when I start plugging numbers in, as I've changed too many things to depend on anything I have written down.