Oooh, that's tough, since both the NSXR and Tiatec have very similar problems with their design. Would you like to kick this one off John?

It really comes down to what the owner is trying to do I guess.

Obviously a big ass wing, albeit it the Taitec or Doug H's home-made mongo aluminum

home depot one will produce effective downforce on a road course. Like putting your hand out the window... that's probably the easy part.

However, every wing design is a balance. What separates a highly optimized computer modeled tunnel tested design from a poor garage tuner design is being maximally effective while minimizing drag so you get the best of both. Further, having it co-exist well with the rest of the vehicle's aerodynamic characteristics and perhaps most sought prove well in the field for the intended course speeds/application/driver.

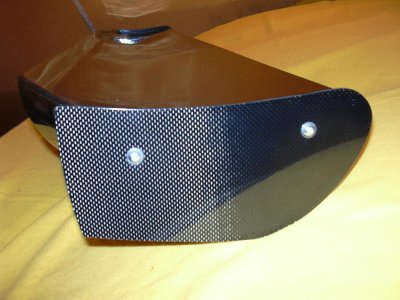

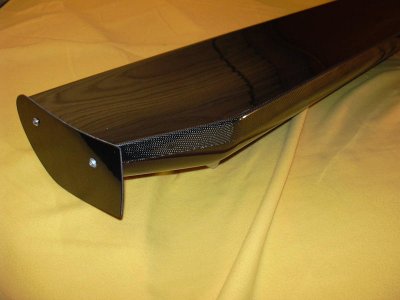

All wings are not created equal. Their are low speed high down-force configurations, multi-element high speed airfoils, multi-surface designs such as a sprint car wing, etc... Even the little end plates and wing mounts design play their part in the effectiveness of the system as a whole.

An interesting trivial point, but from what little I have read historically, they banned mounting wings directly to the lower suspension members, fan cars, and other active aero devices simply because they were so ridiculously effective.. so now all series specify the mount must be to the chassis and a great part of pro R&D goes into simple wing design. Per an issue of Race Car Engineering, in Formula 1, even the composite material layering is optimized via FEA to allow just the perfect amount of flexibility across the span so as to reduce the designs effectiveness at high triple digit straight line speeds as that is 'free' per their rules.

I also wouldn't consider it fair to compare race car aerodynamic goals to that of aerospace... as at sub-sonic and supersonic speeds such as with a airliner, shuttle, or 500,000 mile per hour comet... they use entirely different design software to solve those highly theoretical dynamic problems as drag is a vastly more significant issue to the point where the behavior of each particle hitting the object counts.

The nsx-r wing plus the under flap and small diffuser actualy cleaned up airflow more than create downforce,thus allowing the r to achieve 3-4 more mph at top speed.AFAIK. Also I asked a similar ? a while back

http://www.nsxprime.com/forums/showthread.php?t=60838&highlight=on+a+wing+prayer

For what we do.... from what I can tell most showroom stock sports cars aerodynamics are in fact positive lift. They are primarily optimized for a good top speed spec, maximum fuel efficiency, low noise, road ride height, adequate cooling, etc... Unfortunately, on a road course, this will be relatively slower... and a stock positive lift situation scarier with less predictability at the limit, particularly at higher speeds.

The NSX Type R - due mostly to the ducted hood and other minor tweaks is said by Honda to produce some degree of net downforce. For the envelope of the cars design, I have no doubt that the Showa dampeners, sways, chassis, and everything else is probably very well integrated all things considered as is evident by it's showroom stock lap times.

Still, for the track guys particularly on shorter courses, there is plenty of DIY room to improve- and a big ass wing is of course a well proven tool in every racers toolbox.

The scientific 'manufacturer' approach to prove numbers for a specific wing and mount design is to A-B in a wind tunnel with the car on scales so you can plot downforce versus tunnel speed in real-time and arrive at an exact figure that you can compare to your software model. The problem there is that obviously $1000 an hour to rent one is not realistic for most club enthusiasts. (I guess that's why Taitec wings don't come with CFD vector plots) :biggrin:

Next best- I've never tried it but I've read about a 'drag' test where you can drop your car into neutral and with a data logger measure the interval between a higher and lower speed both with and without the wing. You can then calculate the drag coefficient ratio and arrive back at a good ball park of the wings actual down-force, in pounds for a specific angle of attack.

However, if you really want to get into it..

.. and go 'all out' you can tag some

software and time from someone that specializes in the field, I've noted the sports racers guys really get into it... tell them what you are doing and they will get you steered in the right direction.

Lastly, ask someone in the pro field. Greg Fordahl, whom raced a GT3 cup car in ALMS, told me awhile back that his experience is that no matter how big of a wing you throw on the back he would be surprised to see more than 500lbs of down-force. The under tray they made him buy was like $15,000 and was put to him like 'yeah put this on you'll like it'. He had me raise my mounts slightly to get the wing higher into the clean-air stream and taught me some suspension tricks with the compliance of bump stops to aid in my chassis setup to better compliment aero. But frankly, good enough is good enough.

I think for what we do at the club level... cornering at 55mph-95mph+ on RA1's the GT500, an APR, or even Doug Hiashi's aluminum home depot wing should obviously produce more down-force and show tangible benefits over the stock-ish trunk spoiler by a fairly significant and noticable margin if you have the skills and butt dyno to account for it.

If in doubt, tag a driver you trust for a hot lap and get a second opinion. They say that transponders tell no lies.