This is not the most High Tech Project, but It has worked well enough for me that I thought I should share it.

I wanted a place to mount my iPhone that didn't require permanent modifications to the car, looked best, was located in the best place for my use and was removable. Here is what I came up with.

It should be noted that I now charge the phone with a cable that connects to jack inside my glovebox so the ashtray left closed.

Finished Installation Images:

I started by buying the following magnetic car mount from Amazon:

I then modified it by cutting the flexible shaft to the right length and added a high tech devise to locate and secure it into the mounting sleeve that I manufactured. OK so it is a bit of bent Coat Hanger and some heat shrink tubing. Also note the PVC tubing modified to make the receiver, and the shaft unfitted and fitted.

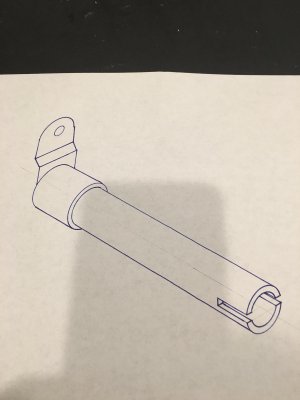

I made a mounting sleeve using 1/2" PVC pipe, a cap, and a mounting flange from a piece of sheetmetal that was screwed into the cap with a sheet metal screw. I didn't take a picture of it before I installed it but made a sketch to show what I did. This was attached to the car under the glovebox using an existing nut and stud on the firewall (through the sheetmetal flange) and three tie wraps to tie the tube to some metal framework that ran from the firewall to the base of the dashboard. I did not glue the cap to the tube so that there was room to access the stud and nut before sliding the tube into the cap.

This is what the tube looks like installed.

And the shaft ready to be inserted.

I wanted a place to mount my iPhone that didn't require permanent modifications to the car, looked best, was located in the best place for my use and was removable. Here is what I came up with.

It should be noted that I now charge the phone with a cable that connects to jack inside my glovebox so the ashtray left closed.

Finished Installation Images:

I started by buying the following magnetic car mount from Amazon:

I then modified it by cutting the flexible shaft to the right length and added a high tech devise to locate and secure it into the mounting sleeve that I manufactured. OK so it is a bit of bent Coat Hanger and some heat shrink tubing. Also note the PVC tubing modified to make the receiver, and the shaft unfitted and fitted.

I made a mounting sleeve using 1/2" PVC pipe, a cap, and a mounting flange from a piece of sheetmetal that was screwed into the cap with a sheet metal screw. I didn't take a picture of it before I installed it but made a sketch to show what I did. This was attached to the car under the glovebox using an existing nut and stud on the firewall (through the sheetmetal flange) and three tie wraps to tie the tube to some metal framework that ran from the firewall to the base of the dashboard. I did not glue the cap to the tube so that there was room to access the stud and nut before sliding the tube into the cap.

This is what the tube looks like installed.

And the shaft ready to be inserted.

Attachments

-

Phone mount Drawing.jpg86.7 KB · Views: 61

Phone mount Drawing.jpg86.7 KB · Views: 61 -

Phone mount Tube installed.jpg256.1 KB · Views: 63

Phone mount Tube installed.jpg256.1 KB · Views: 63 -

Phone Mount Interface uninstalled.jpg126.1 KB · Views: 230

Phone Mount Interface uninstalled.jpg126.1 KB · Views: 230 -

Phone Mount in Car unistalled.jpg237.6 KB · Views: 63

Phone Mount in Car unistalled.jpg237.6 KB · Views: 63 -

Phone Mount in Car unistalled.jpg243.2 KB · Views: 62

Phone Mount in Car unistalled.jpg243.2 KB · Views: 62 -

Phone Mount in Car unistalled.jpg243.1 KB · Views: 228

Phone Mount in Car unistalled.jpg243.1 KB · Views: 228 -

Phone mount Tube installed.jpg260.8 KB · Views: 230

Phone mount Tube installed.jpg260.8 KB · Views: 230 -

Phone mount Drawing.jpg92.2 KB · Views: 230

Phone mount Drawing.jpg92.2 KB · Views: 230 -

Phone Mount Drivers view.jpg205.2 KB · Views: 237

Phone Mount Drivers view.jpg205.2 KB · Views: 237 -

Phone Mount Side View.jpg163.3 KB · Views: 237

Phone Mount Side View.jpg163.3 KB · Views: 237 -

Phone Mount Interface Installed.jpg180.6 KB · Views: 234

Phone Mount Interface Installed.jpg180.6 KB · Views: 234