I've pondered my custom exhaust system for almost a year now. I'm posting this in case others need help building their own custom exhausts. I've followed every single exhaust thread on prime and probably every other exhaust topic available on the internet. I was ready to settle with my trusty HKS muffler but, at times I wanted something louder, more aggressive yet still be completely docile for date night while not hampering horsepower or torque. The units that sound good were too loud for city driving (i.e. GT One V.x's, Gruppe M, Sorcery, etc) and all the ones that were quiet (i.e. HKS, Comptech, etc) weren't aggressive enough for those special times when testosterone gets the best of you. Not to mention, all the loud ones tend to DRONE like no other. I can't tolerate drone because it gives me a migraine.

Inspired by Mac Attack (Thanks Big Mac!) I set forth to design my own. Several versions later it now incorporates a vacuum actuated bypass valve and as well as a quarter-wave resonator. It's really has a Jekyl & Hyde personality. I'm calling it the Harmony Exhaust :biggrin:

Using the NSX's natural vacuum allows for some interesting options.

Option 1 (Throttle Pressure) - By using true vacuum the valve can open and close based on throttle input alone. In other words, when you stomp on it its immediately at full flow, full sound, and 100% gangster regardless of rpm. I've observed the valve tends to open at around 50% throttle. However, to keep the valve closed for when I want it quiet I find myself driving it like I was a Hyper-miler Prius driver. This does lend for an aggressive driving tone for the fwy on-ramps. More effort can be spent fine tuning this by controlling the flow of vacuum.

Option 2 (RPM Dependent) - You can configure the valve to open at 4800 rpms and above (aka VViS). This will open at any level of throttle input but only above 4800. I'm going to drive it more in either option 1 or 2 but I think I prefer Option 2 since it allows for brisk driving around town w/o the need to feather the throttle as much yet still have the option when at WOT.

Option 3 (Wide Open) - Leave it open by incorporating a Hobbs switch to bypass the vacuum. I'll do this when i'm at the track.

Anyway, on to the vids...

I've annotated on this vid to help you understand the valvetronic action - Option 2

<iframe title="YouTube video player" width="480" height="390" src="http://www.youtube.com/embed/tY8mDijgYJk" frameborder="0" allowfullscreen></iframe>

Typical 1st & 2nd gear WOT pull - Option 2

<iframe title="YouTube video player" width="480" height="390" src="http://www.youtube.com/embed/1mkhQrqtV4s" frameborder="0" allowfullscreen></iframe>

The ever popular tunnel video - Option 1 (yes, those people must hate me)

<iframe title="YouTube video player" width="480" height="390" src="http://www.youtube.com/embed/t6EPmZd1mmQ" frameborder="0" allowfullscreen></iframe>

DISCLAIMER:

My camera is terrible. It doesn't remotely capture the volume or fidelity of the sound of this exhaust in real life. This camera sucks!

FAQ's (because i've already been asked )

)

1. Why did I use a bypass valve?

- BMWs, Lambos, Ferraris, and many other exhaust manufacturers since the 60s have implemented this as a way to control exhaust noise and flow. Why not us!

2. Why use a vacuum valve vs. an electric valve?

- Mac Attack has had much success using the electric valve. I tried this one first but the valve just did not open fast enough my intended purpose. A vacuum valve opens and closes almost instantaneously and vacuum tends to the best and easiest measure of throttle input. Either works well. Just depends on what you want.

3. F1 sound?

- LOL, I dare not say for fear of getting crucified. It's somewhat high pitched but I think the sorcery GT center exit is even higher pitched. My version is more of an unrefined fierce bark. It's pretty darn awesome (scary?) and when Kuni drove the NSX, it left me standing with the biggest grin on my face.

4. Why center-exit?

- I wanted to avoid all that extra piping to save weight and i'm in the process of making my diffuser and most exhausts sits too far low. I also think diffusers look funny on the NSX with the dual tips getting in the way. However, I could probably have built this with the traditional dual side exits I suppose. I just bought a used rear valance and cut out the center section.

5. What about Drone?

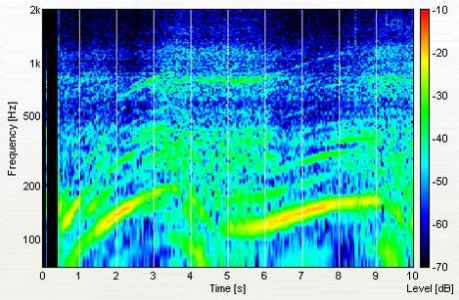

- With help from Mac Attack we were able to isolate the drone frequency. It was occurring between 2000-3000 rpm and at about 130-160hz - every exhaust configuration will yield different drone range. See attached spectrum analysis. By properly placing the valve it doubles as a quarter wave resonator when closed. Genius in its simplicity! It was actually very shocking to me how quiet this is in the cabin when in quiet mode. For the first time in a long time I realized how much wind noise the NSX has on the fwy.. imagine that. It's reminded me of my OEM exhaust from years and years ago.

6. What's next?

- This is just the "Proof of Concept" but i'm so happy with this version that i'll have a local exhaust fabricator remake it to do it up in full mandrel and proper tig welds and much thinner gauge stainless steel piping. I should save about 3lbs(?) from this alone. Right now it weights close to 19lbs because of the crappy 14-16 gauge muffler shop grade piping I used.

Inspired by Mac Attack (Thanks Big Mac!) I set forth to design my own. Several versions later it now incorporates a vacuum actuated bypass valve and as well as a quarter-wave resonator. It's really has a Jekyl & Hyde personality. I'm calling it the Harmony Exhaust :biggrin:

Using the NSX's natural vacuum allows for some interesting options.

Option 1 (Throttle Pressure) - By using true vacuum the valve can open and close based on throttle input alone. In other words, when you stomp on it its immediately at full flow, full sound, and 100% gangster regardless of rpm. I've observed the valve tends to open at around 50% throttle. However, to keep the valve closed for when I want it quiet I find myself driving it like I was a Hyper-miler Prius driver. This does lend for an aggressive driving tone for the fwy on-ramps. More effort can be spent fine tuning this by controlling the flow of vacuum.

Option 2 (RPM Dependent) - You can configure the valve to open at 4800 rpms and above (aka VViS). This will open at any level of throttle input but only above 4800. I'm going to drive it more in either option 1 or 2 but I think I prefer Option 2 since it allows for brisk driving around town w/o the need to feather the throttle as much yet still have the option when at WOT.

Option 3 (Wide Open) - Leave it open by incorporating a Hobbs switch to bypass the vacuum. I'll do this when i'm at the track.

Anyway, on to the vids...

I've annotated on this vid to help you understand the valvetronic action - Option 2

<iframe title="YouTube video player" width="480" height="390" src="http://www.youtube.com/embed/tY8mDijgYJk" frameborder="0" allowfullscreen></iframe>

Typical 1st & 2nd gear WOT pull - Option 2

<iframe title="YouTube video player" width="480" height="390" src="http://www.youtube.com/embed/1mkhQrqtV4s" frameborder="0" allowfullscreen></iframe>

The ever popular tunnel video - Option 1 (yes, those people must hate me)

<iframe title="YouTube video player" width="480" height="390" src="http://www.youtube.com/embed/t6EPmZd1mmQ" frameborder="0" allowfullscreen></iframe>

DISCLAIMER:

My camera is terrible. It doesn't remotely capture the volume or fidelity of the sound of this exhaust in real life. This camera sucks!

FAQ's (because i've already been asked

1. Why did I use a bypass valve?

- BMWs, Lambos, Ferraris, and many other exhaust manufacturers since the 60s have implemented this as a way to control exhaust noise and flow. Why not us!

2. Why use a vacuum valve vs. an electric valve?

- Mac Attack has had much success using the electric valve. I tried this one first but the valve just did not open fast enough my intended purpose. A vacuum valve opens and closes almost instantaneously and vacuum tends to the best and easiest measure of throttle input. Either works well. Just depends on what you want.

3. F1 sound?

- LOL, I dare not say for fear of getting crucified. It's somewhat high pitched but I think the sorcery GT center exit is even higher pitched. My version is more of an unrefined fierce bark. It's pretty darn awesome (scary?) and when Kuni drove the NSX, it left me standing with the biggest grin on my face.

4. Why center-exit?

- I wanted to avoid all that extra piping to save weight and i'm in the process of making my diffuser and most exhausts sits too far low. I also think diffusers look funny on the NSX with the dual tips getting in the way. However, I could probably have built this with the traditional dual side exits I suppose. I just bought a used rear valance and cut out the center section.

5. What about Drone?

- With help from Mac Attack we were able to isolate the drone frequency. It was occurring between 2000-3000 rpm and at about 130-160hz - every exhaust configuration will yield different drone range. See attached spectrum analysis. By properly placing the valve it doubles as a quarter wave resonator when closed. Genius in its simplicity! It was actually very shocking to me how quiet this is in the cabin when in quiet mode. For the first time in a long time I realized how much wind noise the NSX has on the fwy.. imagine that. It's reminded me of my OEM exhaust from years and years ago.

6. What's next?

- This is just the "Proof of Concept" but i'm so happy with this version that i'll have a local exhaust fabricator remake it to do it up in full mandrel and proper tig welds and much thinner gauge stainless steel piping. I should save about 3lbs(?) from this alone. Right now it weights close to 19lbs because of the crappy 14-16 gauge muffler shop grade piping I used.

Attachments

Last edited: