I'm looking to build a reliable NA engine with a little more power and have a few questions. Have built about 50 engines in my life from Chevy to BMW and 911 Porche racing engines (SCCA 2.0 ltr class). My 95 engine has a weak cylinder and it's time to plan a new engine. Rather than lay out $15 grand or so to SOS for a nice stroked engine, I plan to do some of the engineering, parts gathering and assembly myself. No sense paying someone else to do what I know how to do. Besides it's fun to build engines once you understand the prinicples and have learned from a couple of failures  .

.

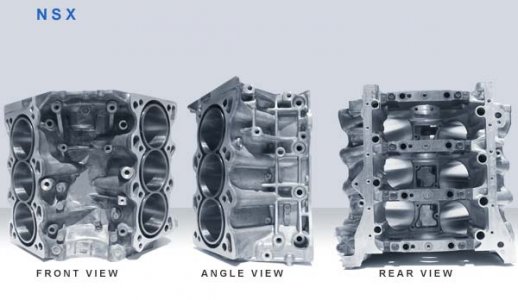

Thinking of Benson sleeving block and having him fit bore to 95mm pistons. Also considering buying an 86 to 88mm stroker crank then use stock rods. The early Comptech Strokers used a similar setup so it is a proven concept. In doing the calculations for buying the correct pistons I need the C30-C32 deck height which I have not been able to find published anywhere. Anybody know what this measurement is? Also, what brand of pistons are recomended? I'm familiar with Mahle-Kolbenschmit pistons. Ideas on machining, cylinder head work, cams, tuning etc. please throw in your ideas. Looking for a value rebuild with a little more oomph! than stock. Thanks everybody!

Stephen

Thinking of Benson sleeving block and having him fit bore to 95mm pistons. Also considering buying an 86 to 88mm stroker crank then use stock rods. The early Comptech Strokers used a similar setup so it is a proven concept. In doing the calculations for buying the correct pistons I need the C30-C32 deck height which I have not been able to find published anywhere. Anybody know what this measurement is? Also, what brand of pistons are recomended? I'm familiar with Mahle-Kolbenschmit pistons. Ideas on machining, cylinder head work, cams, tuning etc. please throw in your ideas. Looking for a value rebuild with a little more oomph! than stock. Thanks everybody!

Stephen