Folks,

I'm finally back to designing a new forced induction system. I'm looking for a new challenge so that eliminates turbos as it's been shown that these can make huge power gains despite poor design and engineering execution. No slam, but with a big enough turbo the sky's the limit (at least for a dyno queen). So that leaves positive displacement SCers which in the past have seem to hit a wall at about 500 RWHP. I decided to start work on incorporating Eaton's new TVS 1900 head unit with the goal of 650 RWHP on my built block (pump gas or E85, don't know).

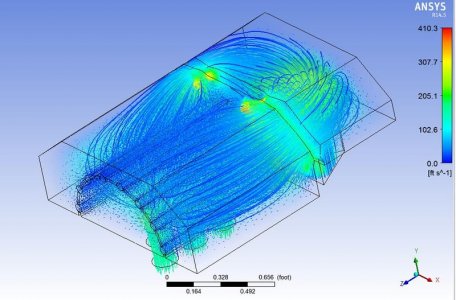

Anyone not aware of the advantages of these new blowers should consult the Eaton website. Even with these improvements I feel the "blower" still has room for further optimization given freedom to design some radically new intake and discharge manifolds to reduce destructive (in terns of flow) acoustical wave dynamics (reduce acoustical impedance), reduce discharge turbulance and promoting optimum air speeds and momentum. The manufacture has requirements for the masses that allow easier adaption to various applications but which also sub-optimise performance. I don't have these constraints.

Anyway, I'm 50% into my design effort having scanned in and converted to CAD models all the major engine components so I can do some what-if product packaging and output CAD parts ready for the CNC machine. Then I see this Procharger SCer on some gear head TV show. It's has a variable speed (like a snowmobile) trans which is controlled by an electrical servo (motor) which is programable. Bottom line, this centrifugal SCer has the potential to erase the complaints about poor low rpm boost while keeping the great top end performance. I was intrigued so I called Procharger.

To make a long conversation short Procharger isn't selling the blower alone, just in kit form (they have a few muscle car kits to date at over $8k). They're DISCOURAGING tuner installations as they feel the unit is just too new. Consequently they won't provide any technical support unless it's associated with one of their kits. I asked about sending me an IGES, STL, or STEP file of the head unit so I can do some "what-if's" to determine if the darn thing would even fit in the engine bay and they said no due to worries about reverse engineering efforts. It's clear this engineer doesn't understand that you can't do much with these "dumb" models and I got 10 times more insight into their design by watching the Procharger generated simulation video on their own website than I could ever get studying a surface model. He was either being very vague regrading many of my questions or simply didn't understand the technical lingo. Either way I came away quite discouraged about any thoughts of incorporating this new technology (well it's old tech with a new twist) into my NSX.

So I guess it's back to the new Eaton 1900. Probably just as well as the Procharger is HUGE and probably hogs HP like crazy with that variable ratio box. Curious, Procharger told me they didn't even measure the HP required to pump various flows at various pressure ratios.

Back to what's in it for YOU. Once I've reached my goal on my personal car I'm going to use a similar design concept but using the older (and very cheap) M90 blower. I've got a design where I'll plumb the output of the SCer into the stock TB and intake just like a turbo making the installation much, much simpler. My market would be someone wanting 60 to 80 extra HP at low boost/rpm. This should avoid having to go to a stand alone EMS by simply regulating fuel pressure and a few other easy parameters to make the system safe. I suspect the price with a customer supplied used (e-bay) blower would be less than $3000.

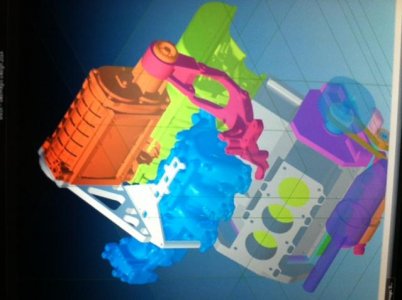

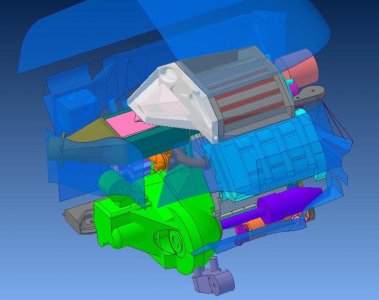

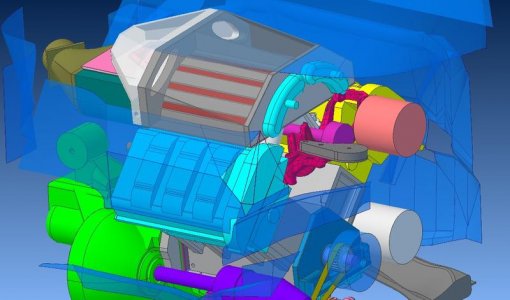

Here's my engine model and my Creaform 3D scanner used to capture parts as point cloud data.

I'm finally back to designing a new forced induction system. I'm looking for a new challenge so that eliminates turbos as it's been shown that these can make huge power gains despite poor design and engineering execution. No slam, but with a big enough turbo the sky's the limit (at least for a dyno queen). So that leaves positive displacement SCers which in the past have seem to hit a wall at about 500 RWHP. I decided to start work on incorporating Eaton's new TVS 1900 head unit with the goal of 650 RWHP on my built block (pump gas or E85, don't know).

Anyone not aware of the advantages of these new blowers should consult the Eaton website. Even with these improvements I feel the "blower" still has room for further optimization given freedom to design some radically new intake and discharge manifolds to reduce destructive (in terns of flow) acoustical wave dynamics (reduce acoustical impedance), reduce discharge turbulance and promoting optimum air speeds and momentum. The manufacture has requirements for the masses that allow easier adaption to various applications but which also sub-optimise performance. I don't have these constraints.

Anyway, I'm 50% into my design effort having scanned in and converted to CAD models all the major engine components so I can do some what-if product packaging and output CAD parts ready for the CNC machine. Then I see this Procharger SCer on some gear head TV show. It's has a variable speed (like a snowmobile) trans which is controlled by an electrical servo (motor) which is programable. Bottom line, this centrifugal SCer has the potential to erase the complaints about poor low rpm boost while keeping the great top end performance. I was intrigued so I called Procharger.

To make a long conversation short Procharger isn't selling the blower alone, just in kit form (they have a few muscle car kits to date at over $8k). They're DISCOURAGING tuner installations as they feel the unit is just too new. Consequently they won't provide any technical support unless it's associated with one of their kits. I asked about sending me an IGES, STL, or STEP file of the head unit so I can do some "what-if's" to determine if the darn thing would even fit in the engine bay and they said no due to worries about reverse engineering efforts. It's clear this engineer doesn't understand that you can't do much with these "dumb" models and I got 10 times more insight into their design by watching the Procharger generated simulation video on their own website than I could ever get studying a surface model. He was either being very vague regrading many of my questions or simply didn't understand the technical lingo. Either way I came away quite discouraged about any thoughts of incorporating this new technology (well it's old tech with a new twist) into my NSX.

So I guess it's back to the new Eaton 1900. Probably just as well as the Procharger is HUGE and probably hogs HP like crazy with that variable ratio box. Curious, Procharger told me they didn't even measure the HP required to pump various flows at various pressure ratios.

Back to what's in it for YOU. Once I've reached my goal on my personal car I'm going to use a similar design concept but using the older (and very cheap) M90 blower. I've got a design where I'll plumb the output of the SCer into the stock TB and intake just like a turbo making the installation much, much simpler. My market would be someone wanting 60 to 80 extra HP at low boost/rpm. This should avoid having to go to a stand alone EMS by simply regulating fuel pressure and a few other easy parameters to make the system safe. I suspect the price with a customer supplied used (e-bay) blower would be less than $3000.

Here's my engine model and my Creaform 3D scanner used to capture parts as point cloud data.