- Joined

- 31 August 2024

- Messages

- 1

Whats up everyone, I took in my 91' NSX in to a local car body shop as the right passenger fender got bent hoping to get it bent back in place and add a bit of a touchup. (First 2 images)

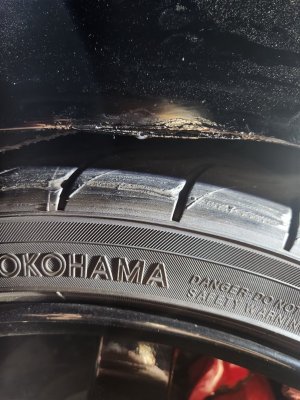

Body shop overbent it and its now in two pieces. (Last 4 images)

What should be my next move in addressing this issue?

Body shop overbent it and its now in two pieces. (Last 4 images)

What should be my next move in addressing this issue?