I have been designing and working on making a design of titanium lugs nuts that I like for about 4 months now. This has mainly taken so long cause I'm having to fit this in with school and working on my Z.

-I have them the shape I now want after 4 tries.

-I have the heat treatment pattern now how I want after 9 tries.

-I do not have the matte finish I I want on them though, and I am curious if any of you know how it is done. If you do, and your way works I'll give you for free a set of these lug nuts.

Basically, the way mine are now...when they are done getting milled, they obviously have a shiny look to them. Then I heat treat them and they are done. Everything looks great, but if there was a way I could have them matte finished instead, then heat treated, that would be awesome. It will look better, and bring out the color a lot more as well.

I assumed that etching the lugs with sandblasting or acid would do the job. After doing these processes to a lugnut, they were in fact matte finished, BUT when I then went to heat treat them, the treatment did everything very weird and did not make normal color bands.I have tried acid and/or sandblasting 6 different ways now, and now way works at all once the heat treatment is applied.

After talking to some people, I have come to the conclusion that campanies are attaining these matte looks by a coating on the surface, then hat treating that. I just don't know what that coating is.

If any of you all know what I mean, please do let me know, as I really do want to have these on my car. The glossy look does look great, but I know matte will be even better.

Thanks! Here pictures of what I am talking about.

I don' thavea picture o fmy exact lugs on this computer, so this will have to do.

Here is a glossy heat treated look (Not a fan of these colors but this pic will have to do)

Here is an example of a matte finished lugnut. Notice how much better the color is brought out.

-I have them the shape I now want after 4 tries.

-I have the heat treatment pattern now how I want after 9 tries.

-I do not have the matte finish I I want on them though, and I am curious if any of you know how it is done. If you do, and your way works I'll give you for free a set of these lug nuts.

Basically, the way mine are now...when they are done getting milled, they obviously have a shiny look to them. Then I heat treat them and they are done. Everything looks great, but if there was a way I could have them matte finished instead, then heat treated, that would be awesome. It will look better, and bring out the color a lot more as well.

I assumed that etching the lugs with sandblasting or acid would do the job. After doing these processes to a lugnut, they were in fact matte finished, BUT when I then went to heat treat them, the treatment did everything very weird and did not make normal color bands.I have tried acid and/or sandblasting 6 different ways now, and now way works at all once the heat treatment is applied.

After talking to some people, I have come to the conclusion that campanies are attaining these matte looks by a coating on the surface, then hat treating that. I just don't know what that coating is.

If any of you all know what I mean, please do let me know, as I really do want to have these on my car. The glossy look does look great, but I know matte will be even better.

Thanks! Here pictures of what I am talking about.

I don' thavea picture o fmy exact lugs on this computer, so this will have to do.

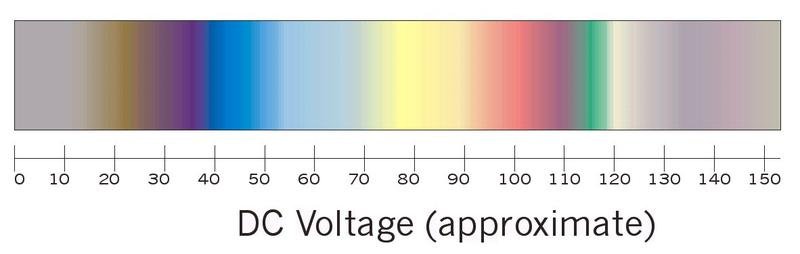

Here is a glossy heat treated look (Not a fan of these colors but this pic will have to do)

Here is an example of a matte finished lugnut. Notice how much better the color is brought out.