Hey Doug,

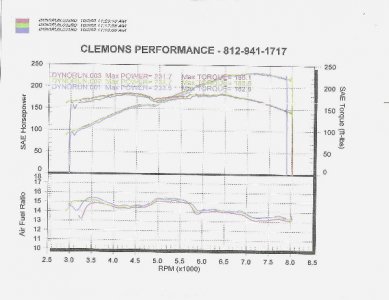

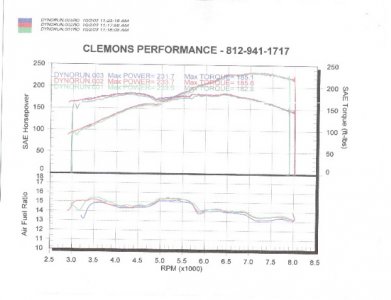

Thanks for taking the time to post your results. It has been awhile since I have had a chance to see results along with the a/f plots. The NSX, I'll have to say, is really strange in the range of 4800-5800 rpm. I see this consistently in FI charts that I have analyzed and tuned and here it is again showing up in stock form. Frankly, it really doesn't surprise me as I knew this odd section must exist in the baseline if it was so consistently present in the FI charts.

There is a lean spot in this range and you can see that it has a rather dramtic effect on the HP/Torque curves. (See them both tick down when this lean spot occurs and then recover when you get into some better a/f's right about 5800 rpm.)

There is nothing really to worry about with a NA engine. You may want to run some fuel injector cleaner and/or remove them and have them sent out for cleaning/balancing. If you decide to do the later, it would be really interesting to see the "after" results - namely to see if it had any effect.

Anyway, congrats on having/maintaining a car that show up so strongly on the dyno after a mere 100K miles.