This is an illustrated write up of how to hook up a horn to a momo (nsx-r type) hub, for use with an aftermarket wheel - as a bit of a disclaimer I am borrowing the wiring diagram for the horn button from the nsxbuilder.com website, which helped me greatly during my install. Prior to starting the momo hub installation I read several writeups here on nsxprime, unfortunatly when it came to the horn most of these writeups ended with "then fabricate something to attach to the back of the momo hub" - having never installed an aftermarket hub before this gave me a bit of pause, although it is exactly what you need to do, the following are pictures of the 'something' I decided to use, and the best part is its using off the shelf parts with no drilling, etc.

This is assuming you already know how to, or have already finished, installing the momo hub, and are looking to install the horn.

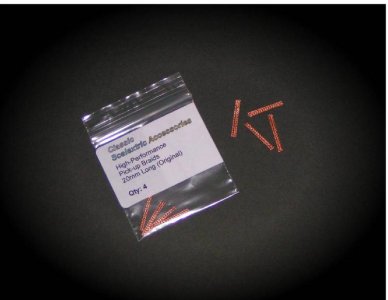

The missing link, 1/2" copper tube straps, from home depot:

One such tube strap, in all its glory:

Bent, for use on the car:

This copper tube strap mounts to one of the original screw posts for the cable reel from the OEM wheel, simply take one of the cable reel mounting screws, pass it through the tube strap, and bolt it in place - prior to tightening it down all the way pass an exposed end of a length of wire in between the two ends of the tube strap, like so:

The momo hub is visible on the left, this is the right-most screw post for the OEM cable reel - there is a 12" length of wire sandwiched in the tube strap, and the screw that secures this to the car is tightened down.

Next find your OEM yellow harness, that attached to the original steering wheel - with the other end of your 12" length of wire stick it in pin position #1, as seen in this diagram (from http://www.nsxbuilder.com):

Now, tighten down the nut that secures your momo hub to the car - remember to place the 'turning signal' un-clicker plastic piece in the correct orientation with regards to the hub - once the hub is secured to the car get on your back and look at the back of the hub - ensure your copper tube strap is in contact with the copper ring around the back of the hub - if it is you are 90% complete.

Next you are going to attach the steering wheel to the hub, prior to doing so get yourself another length of wire, this time much smaller (around 4" should be fine) with exposed ends - sandwich one end of this wire between the hub and the steering wheel, and tighten the wheel to the hub, like so (red wire):

The red wire is in contact with the hub, it is your ground - the black wire, built into the hub, is connected to the copper ring around the back of the hub, which is connected to your yellow OEM wiring harness - you connect the two and your horn will beep - wrap one end of the small 4" ground wire around one of the two contacts of your horn button, and attach the black wire built into the momo hub to the other - give the horn button a light push, and it should beep - simply snap the horn button into the aftermarket wheel and you are done.

This is assuming you already know how to, or have already finished, installing the momo hub, and are looking to install the horn.

The missing link, 1/2" copper tube straps, from home depot:

One such tube strap, in all its glory:

Bent, for use on the car:

This copper tube strap mounts to one of the original screw posts for the cable reel from the OEM wheel, simply take one of the cable reel mounting screws, pass it through the tube strap, and bolt it in place - prior to tightening it down all the way pass an exposed end of a length of wire in between the two ends of the tube strap, like so:

The momo hub is visible on the left, this is the right-most screw post for the OEM cable reel - there is a 12" length of wire sandwiched in the tube strap, and the screw that secures this to the car is tightened down.

Next find your OEM yellow harness, that attached to the original steering wheel - with the other end of your 12" length of wire stick it in pin position #1, as seen in this diagram (from http://www.nsxbuilder.com):

Now, tighten down the nut that secures your momo hub to the car - remember to place the 'turning signal' un-clicker plastic piece in the correct orientation with regards to the hub - once the hub is secured to the car get on your back and look at the back of the hub - ensure your copper tube strap is in contact with the copper ring around the back of the hub - if it is you are 90% complete.

Next you are going to attach the steering wheel to the hub, prior to doing so get yourself another length of wire, this time much smaller (around 4" should be fine) with exposed ends - sandwich one end of this wire between the hub and the steering wheel, and tighten the wheel to the hub, like so (red wire):

The red wire is in contact with the hub, it is your ground - the black wire, built into the hub, is connected to the copper ring around the back of the hub, which is connected to your yellow OEM wiring harness - you connect the two and your horn will beep - wrap one end of the small 4" ground wire around one of the two contacts of your horn button, and attach the black wire built into the momo hub to the other - give the horn button a light push, and it should beep - simply snap the horn button into the aftermarket wheel and you are done.