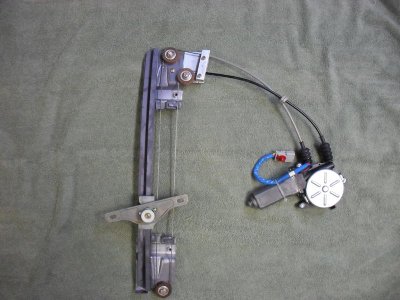

I had some time last year (in Afghanistan) and thought that I would improve on the single pulley window regulator modification. Hugo got rid of most of the drag with the replacement of the bottom cable guide. I felt that more drag could be removed with using pulleys on the top two guides also. Anyway, here is what I came up with. I used aircraft quality pulleys which are a MS 20219-1 that can be purchased from Aircraft Spruce for $18.90 ea.

http://www.aircraftspruce.com/catalog/appages/phenolicpulleys.php

these are really smooth bearing pulleys.

I am also making (having made) new guides for the trolley that rides on the "I" beam. It will be a few weeks before they are ready (in quantities with a very reasonable price).

My next project will be to adapt a more powerful motor to our regulators. I think that a late model Acura CL window regulator will be where I start.

Brad

http://www.aircraftspruce.com/catalog/appages/phenolicpulleys.php

these are really smooth bearing pulleys.

I am also making (having made) new guides for the trolley that rides on the "I" beam. It will be a few weeks before they are ready (in quantities with a very reasonable price).

My next project will be to adapt a more powerful motor to our regulators. I think that a late model Acura CL window regulator will be where I start.

Brad